Creating a New Green Appearance

Creating a New Green Appearance Air pollution management and prevention

Air pollution management and prevention Air pollution management and prevention

Air pollution management and prevention

Creating a New Green Appearance

Creating a New Green Appearance Air pollution management and prevention

Air pollution management and prevention Air pollution management and prevention

Air pollution management and prevention Management Approach (MA) for Material Topic

Air Quality Impacts Evaluation and Consultation Committee

Due to public concern of air pollutant emission from Mailiao Industrial Park affecting the air quality in Yunlin, Chiayi, and Tainan, we established the "Evaluation and Consultation Committee for Impacts on Air Quality by Mailiao Industrial Park," and actively communicate with stakeholders through industry-academia collaboration and community communication.

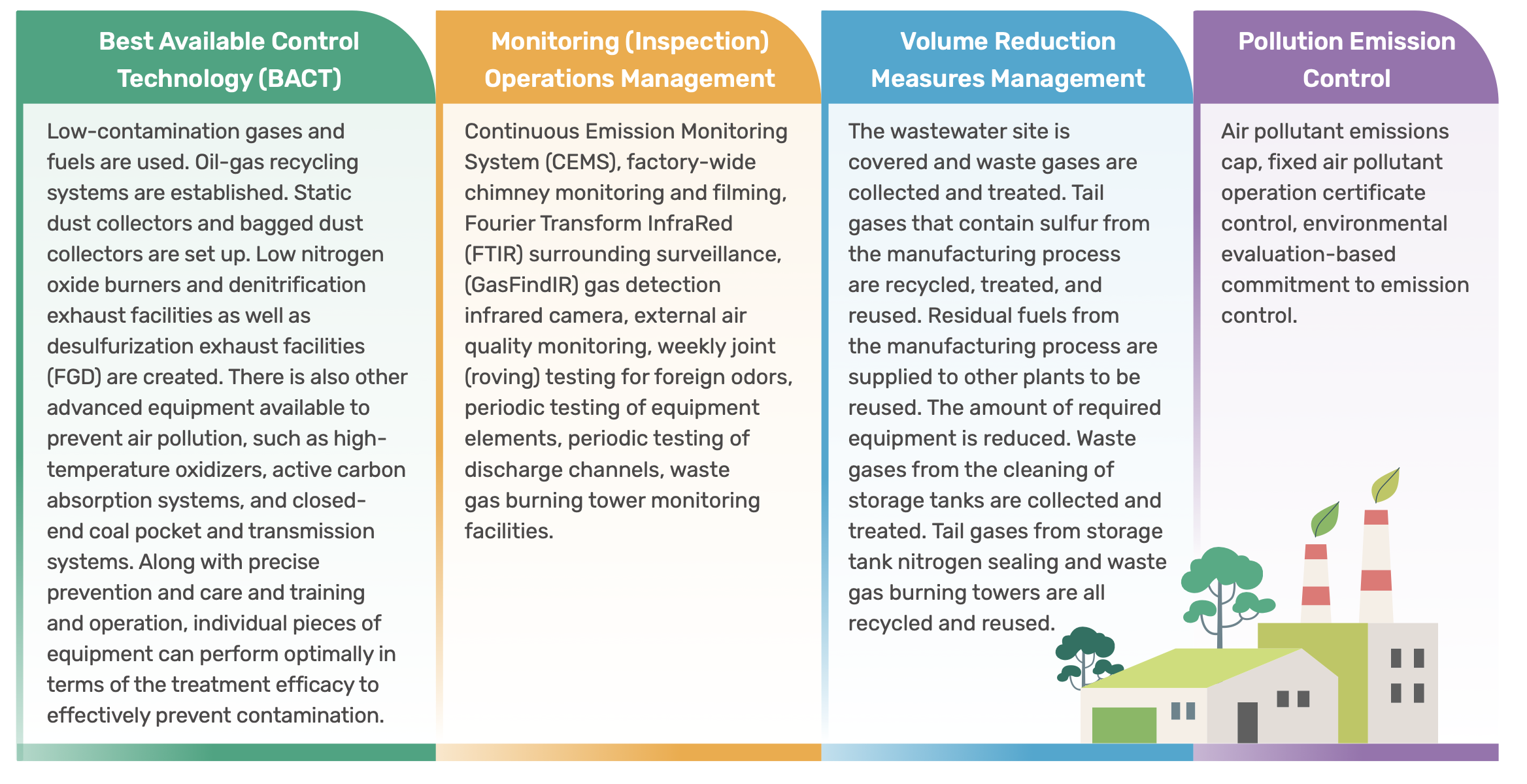

Air Pollution and Waste Gas Management

To understand the impacts of emissions on the environment and people's health, we comprehensively adopted the best available control technology (BACT), as well as the world's most advanced process improvement and pollution prevention technologies.

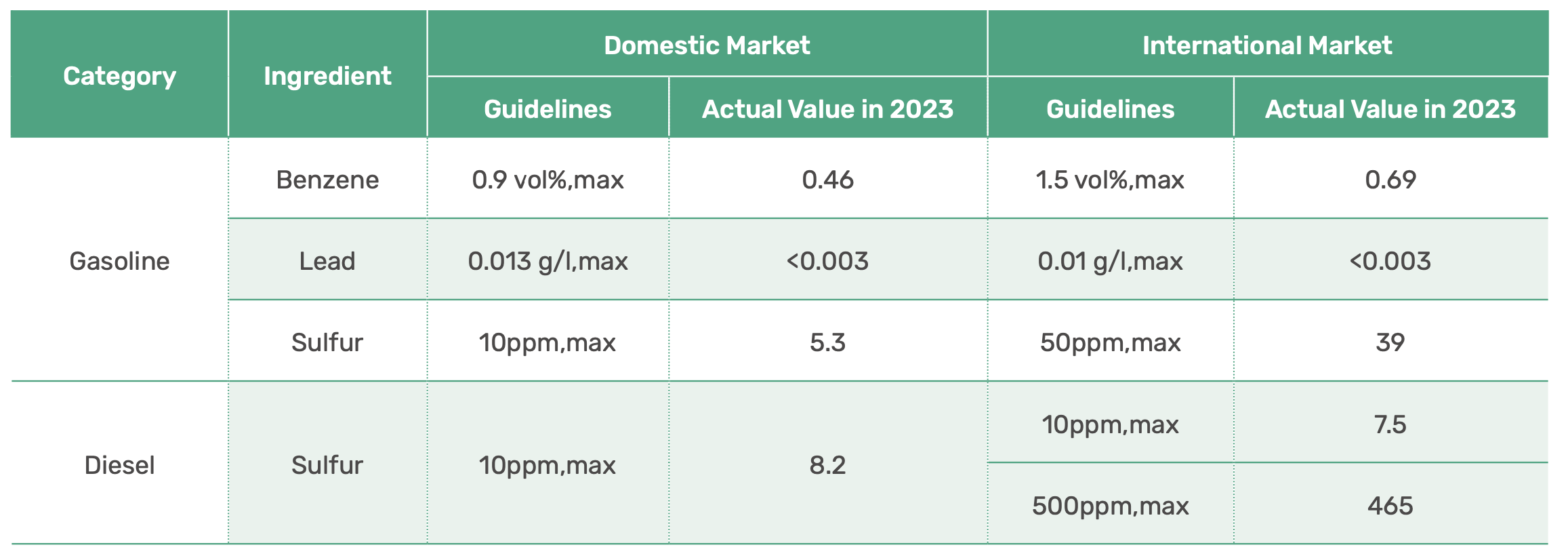

The Company began complying with international standards and follows the government's policy to ban the use of halons, CFC-11, and CFC-12 since it was established in 1992. Now, R-134a, R-401a, and R-410a are the main coolants used, and sulfur and benzene contents in gasoline and diesel products strictly follow regulations of the European Union.

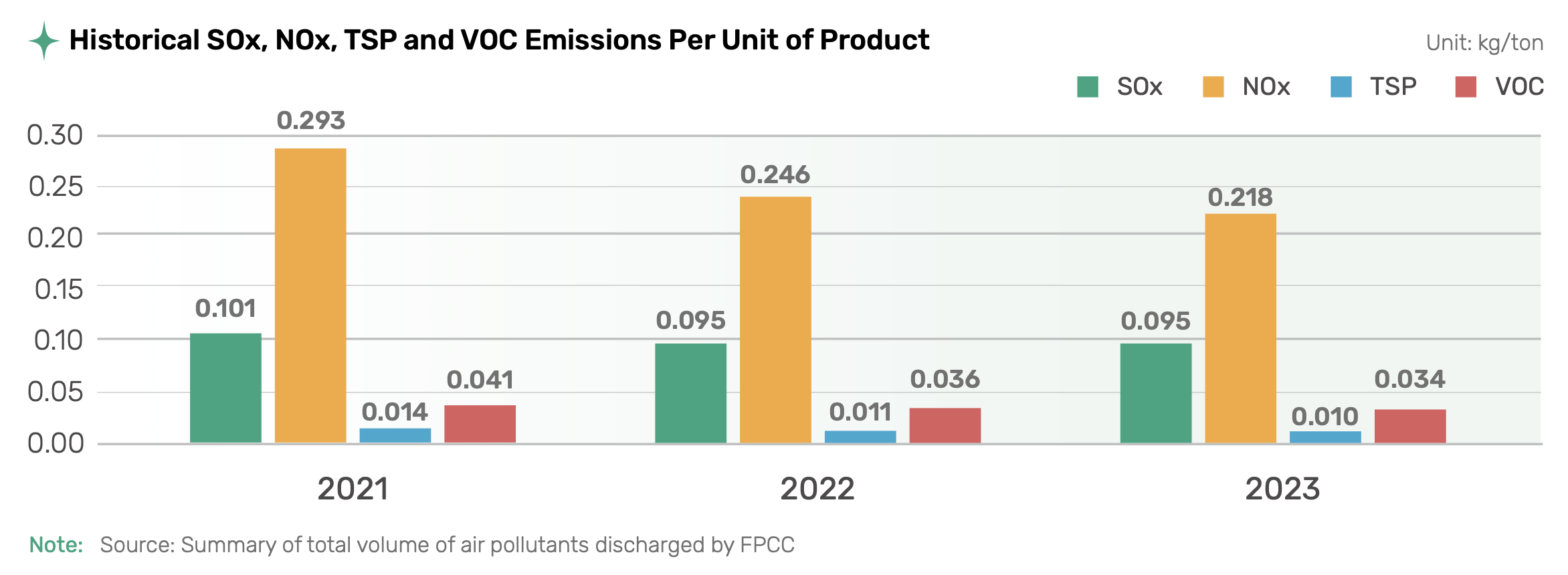

The best available pollution prevention equipment is used for air pollution prevention. In 2023, the total production capacity was 30,234.8 thousand tons, sulfur oxides (SOx) emission per unit of product was 0.095 kg/tons and nitrogen oxides (NOx) was 0.218 kg/tons.

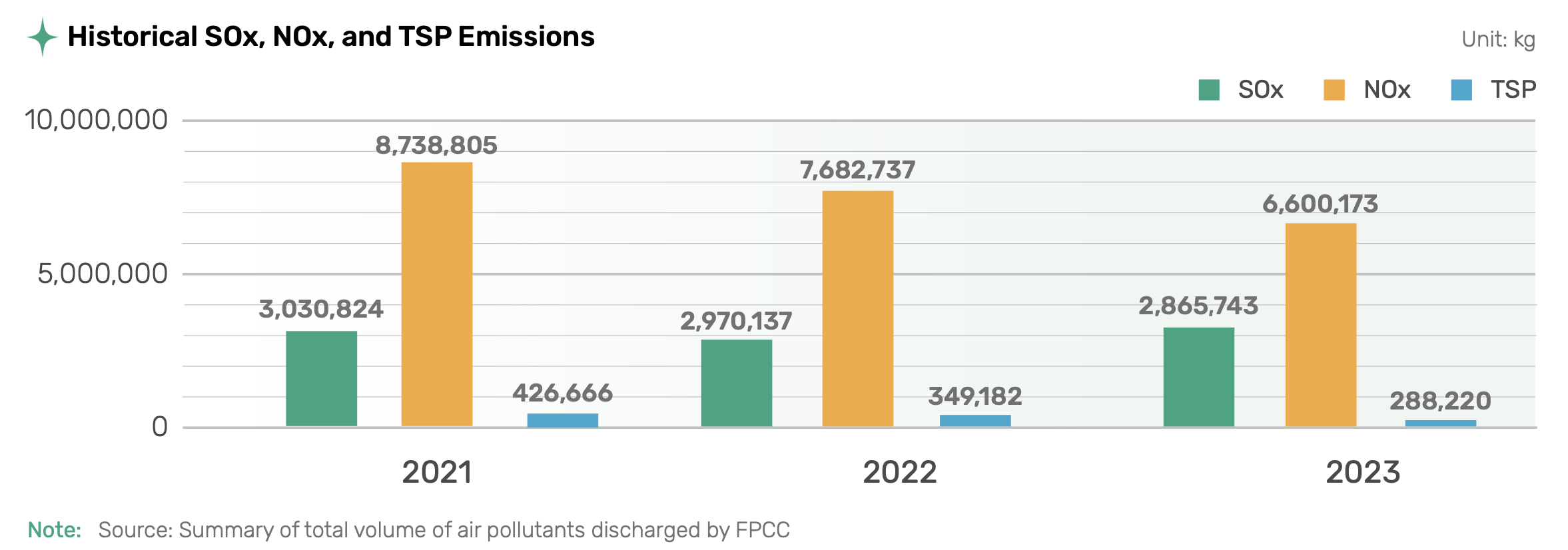

SOx emissions was 2,865,743 kg, NOx emissions was 6,600,173 kg, and TSP emissions was 288,220 kg in 2023.

Our SOx, NOx, and TSP emissions in 2023 were lower than 2022, and was mainly due to the total production capacity of 30,234.8 thousand tons in 2023 being lower than the 31,192.7 thousand tons in 2022. In the future, we will continue to reduce emissions of SOx, NOx, and TSP per unit product, continue to add air pollution reduction equipment, add the most suitable amount of ammonia, and plan the use of low sulfur fuels in processes.