- Overview

- Employee Structure

- Employee Career Development

- Employee Benefits and Care

- Occupational Health and Safety

Contractor Management

The Company convenes daily toolbox meetings and monthly coordination organization meetings to communicate, promote, and discuss safety and health with contractors. Requirements that must be immediately met are communicated through the messaging group between the Company's engineering department and contractors. Contractors can use the group to ask questions at any time, and the Company's personnel will immediately respond and provide assistance.

Continue to Implement Contractor Self-Management and Jointly Improve Self-Management Abilities of Suppliers

-

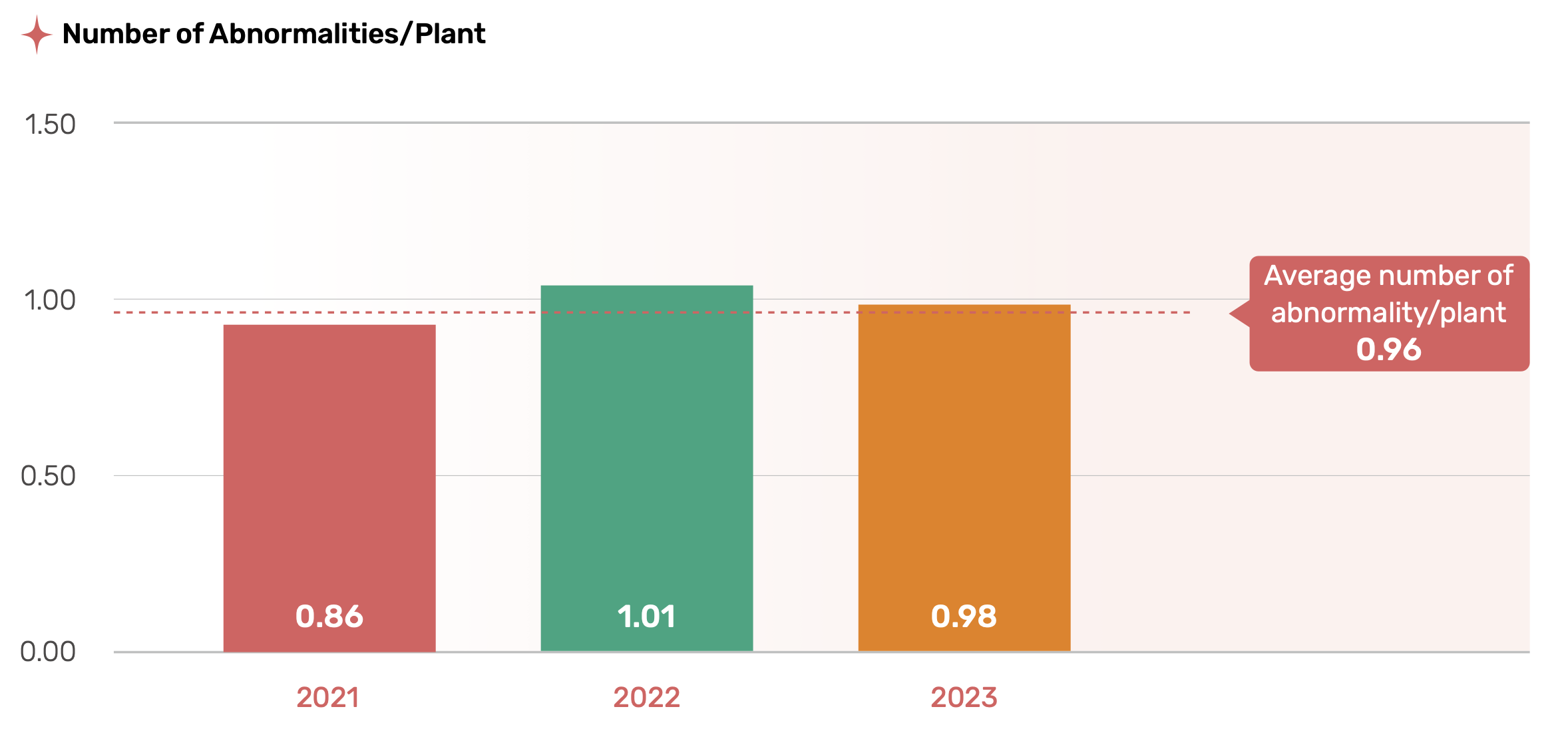

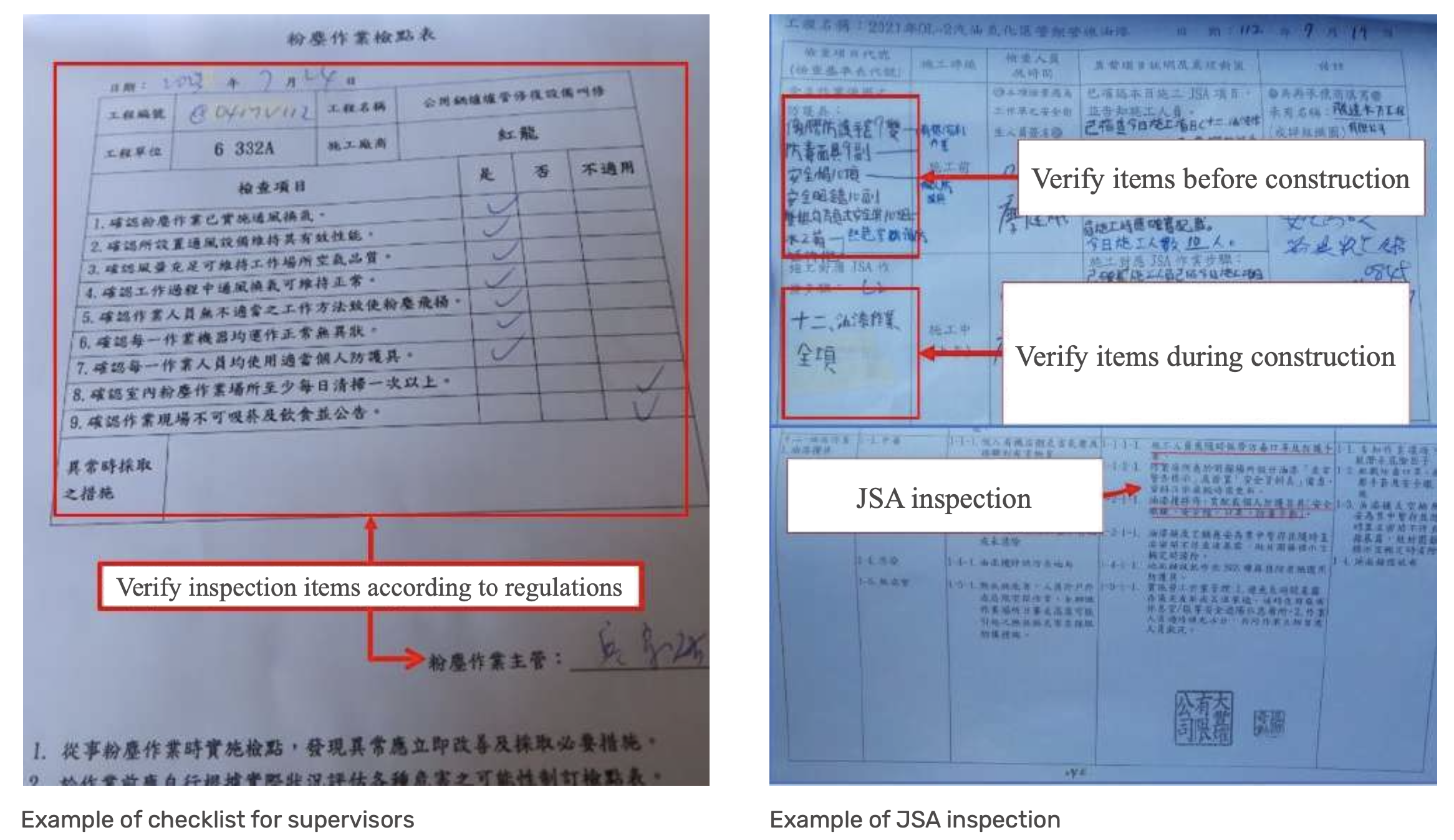

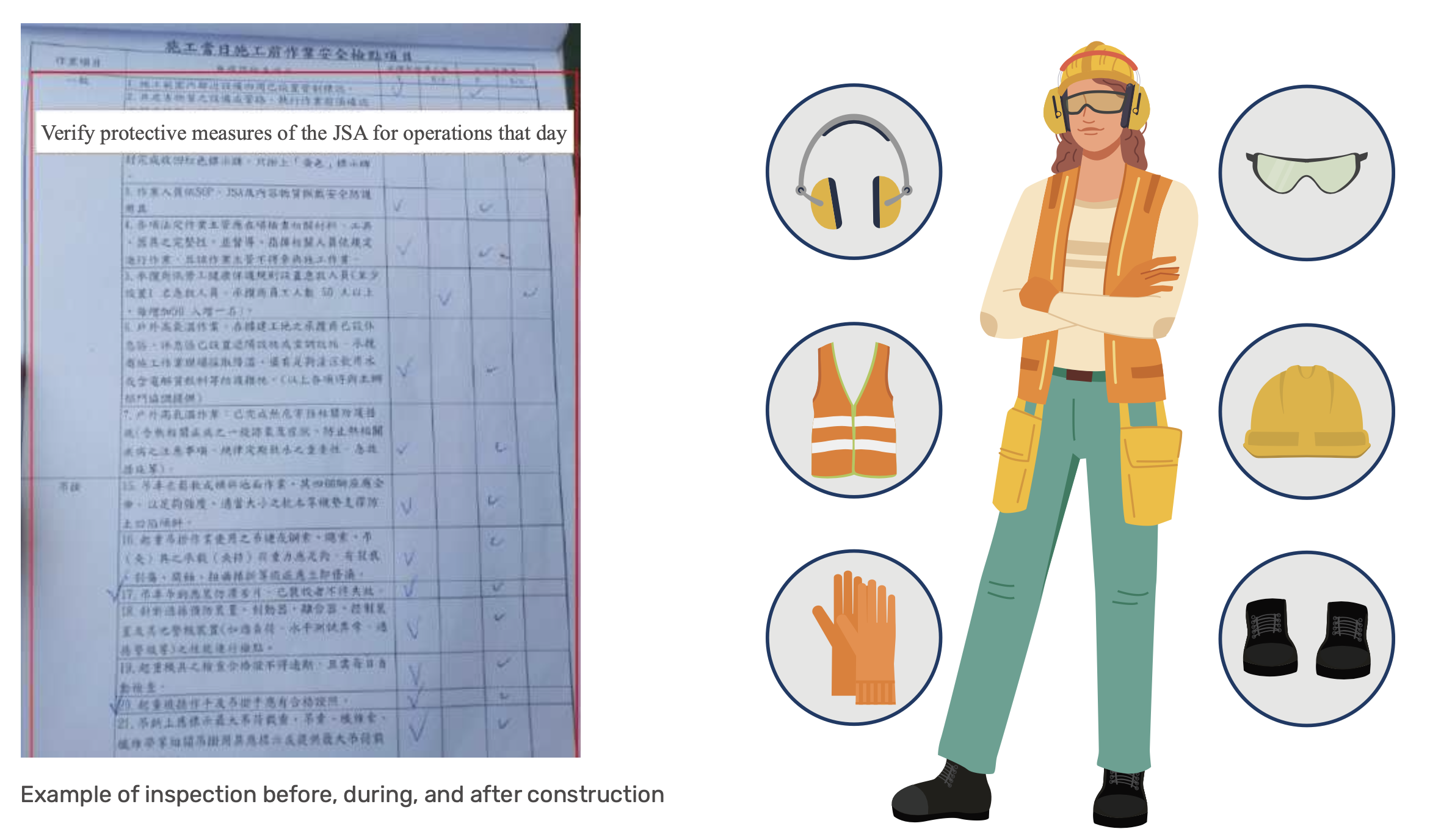

Self-inspections before, during, and after construction by labor safety personnel of contractors.

-

JSA inspection of protective equipment worn by labor safety personnel of contractors.

Before construction, check if all protective equipment required for JSA that day equipment is prepared and effective. During construction, check if personnel are properly using protective equipment for the procedure. -

Inspection by operations supervisor of contractor:

The supervisor of operations by contractors performs inspections using the checklist before construction commences each day and supervises operations on site according to the Occupational Health and Safety Act.

Compliance Audit

Process Safety

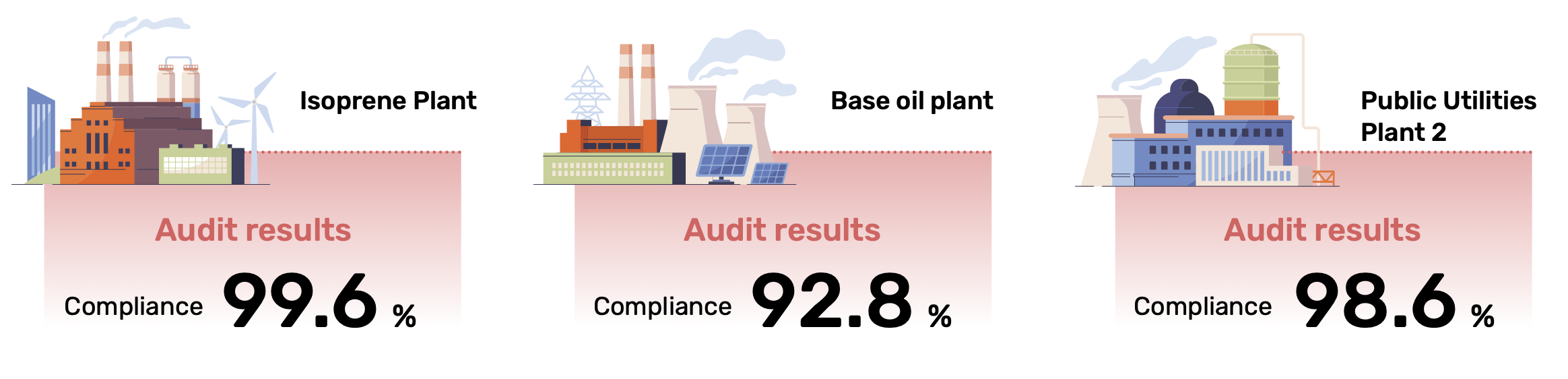

To verify the implementation status of PSM, an external agency is engaged every 5 years starting in 2023 to complete compliance audits of each unit. In 2023, 3 factory audits (3 days per factory) were completed with an average compliance of 97%.

Occupational Safety

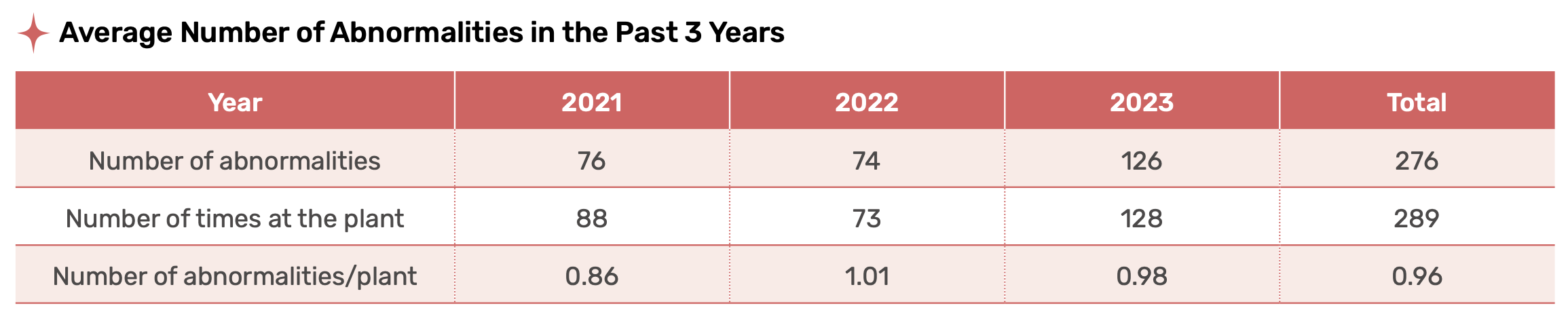

We verify the implementation results of safety and health management systems and compliance of units through monthly compliance audits and project audits. Average number of abnormalities was 0.98 abnormalities/plant in 2023, higher than the average of 0.96 abnormalities/plant in the most recent three years.

In addition to regular inspections this year, the inspection of contractor operations during regular inspections was also strengthened, and "contractor self-management and inspection implementation" was listed as a key audit item. The number of abnormalities increased slightly (the total number of abnormal cases increased from 18% to 27%). The number of abnormal cases in elevated operations (including scaffold management) decreased (the total number of abnormal cases decreased from 26% to 22%), and will continue to be included as a key audit item in 2024 after review.